Discovering the Uses of Membrane Switch Over in Various Industries

Membrane layer switches are integral parts throughout numerous sectors, including consumer electronics and automotive markets. Their light-weight and long lasting nature permits effective use in compact gadgets. On top of that, these buttons give resistance to environmental elements, boosting their durability. As sectors progress, the need for personalized options grows. This raises crucial inquiries about the future applications and innovations of membrane button modern technology. What new possibilities lie in advance for this functional part?

Membrane Changes in Consumer Electronics

Membrane layer switches play a crucial duty in consumer electronics, offering a reliable user interface for various tools. These switches are developed to be slim and light-weight, making them optimal for contemporary devices where area is at a premium. Their versatility permits assimilation into varied products, varying from house devices to portable devices. The tactile responses given by membrane layer switches improves individual interaction, guaranteeing a seamless experience.Moreover, membrane layer buttons are resistant to dampness and dust, which is necessary for keeping performance in day-to-day settings. They can be personalized with numerous graphics and colors, allowing suppliers to align with branding requirements. In addition, the cost-effectiveness of membrane layer switch technology makes it a favored selection for mass-produced electronics. As customer demand for streamlined, straightforward tools remains to expand, the value of membrane buttons in supplying trustworthy, reliable interfaces comes to be significantly noticeable, solidifying their place in the electronic devices market.

Applications in the Automotive Sector

In the auto market, membrane buttons are made use of to boost both capability and aesthetic appeal within lorries. These switches are generally incorporated into dashboards, control board, and infotainment systems, providing a streamlined and contemporary interface for travelers and motorists. Their design permits seamless combination with different materials, which adds to the general aesthetic appeal of the car's interior.Furthermore, membrane switches are valued for their longevity and resistance to environmental variables such as wetness, dirt, and temperature changes. This makes them optimal for applications in auto settings, where reliability is essential. Furthermore, they can be tailored with various graphics and designs, enabling producers to create distinct branding aspects and individual experiences.As automotive technology remains to develop, the need for innovative control options will likely drive better improvements in membrane layer switch applications, ensuring they stay a vital part in contemporary car style.

The Role of Membrane Switches in Healthcare

Often ignored, the duty of membrane layer buttons in healthcare is crucial for guaranteeing the effective procedure of medical tools and equipment. These buttons work as interface for a range of applications, consisting of analysis makers, individual monitoring systems, and surgical instruments. Their design permits easy cleaning and sterilization, which is vital in preserving health in medical environments.Membrane switches are additionally recognized for their longevity and resistance to put on, making them optimal for gadgets that sustain constant usage. Their responsive responses offers users with a dependable experience, boosting functionality for medical care experts. On top of that, membrane layer switches can be tailored with numerous graphics and designs, making sure that they fulfill details requirements of different clinical applications. In general, the combination of membrane layer buttons in medical care modern technology not only boosts performance but additionally adds to patient security and functional efficiency within clinical facilities.

Aerospace Innovations With Membrane Layer Switch Innovation

Industrial Automation and Membrane Change Solutions

Membrane switch technology is significantly finding applications in industrial automation, where integrity and effectiveness are paramount. These switches visit the website act as important parts in various automated systems, facilitating user interactions in environments that demand effectiveness and durability. Their layout permits a seamless integration with control panels and devices, making sure ease of use for operators.In commercial setups, membrane layer buttons can stand up to extreme problems, including exposure to dust, moisture, and severe temperatures. This durability makes them perfect for applications in production, logistics, and process control. Furthermore, their personalized functions make it possible for business to create customized solutions pop over to this web-site that fulfill particular functional needs.The responsive responses provided by membrane switches over improves individual experience, decreasing the likelihood of errors during procedure - membrane switch. As industries remain to advance in the direction of higher automation, the role of membrane layer switch modern technology is expected to broaden, enhancing and driving efficiencies process in complicated commercial atmospheres

Frequently Asked Concerns

What Products Are Commonly Made Use Of in Membrane Change Building And Construction?

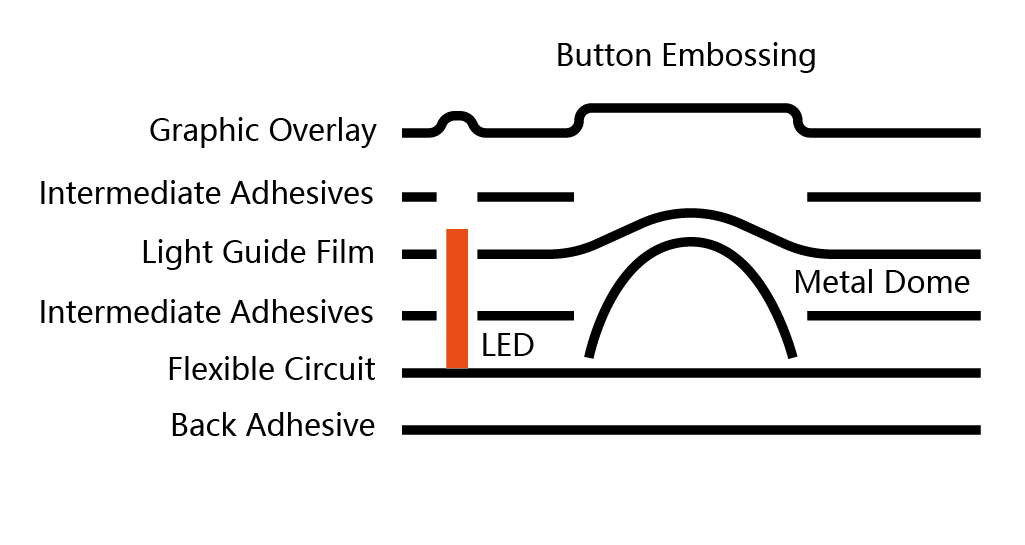

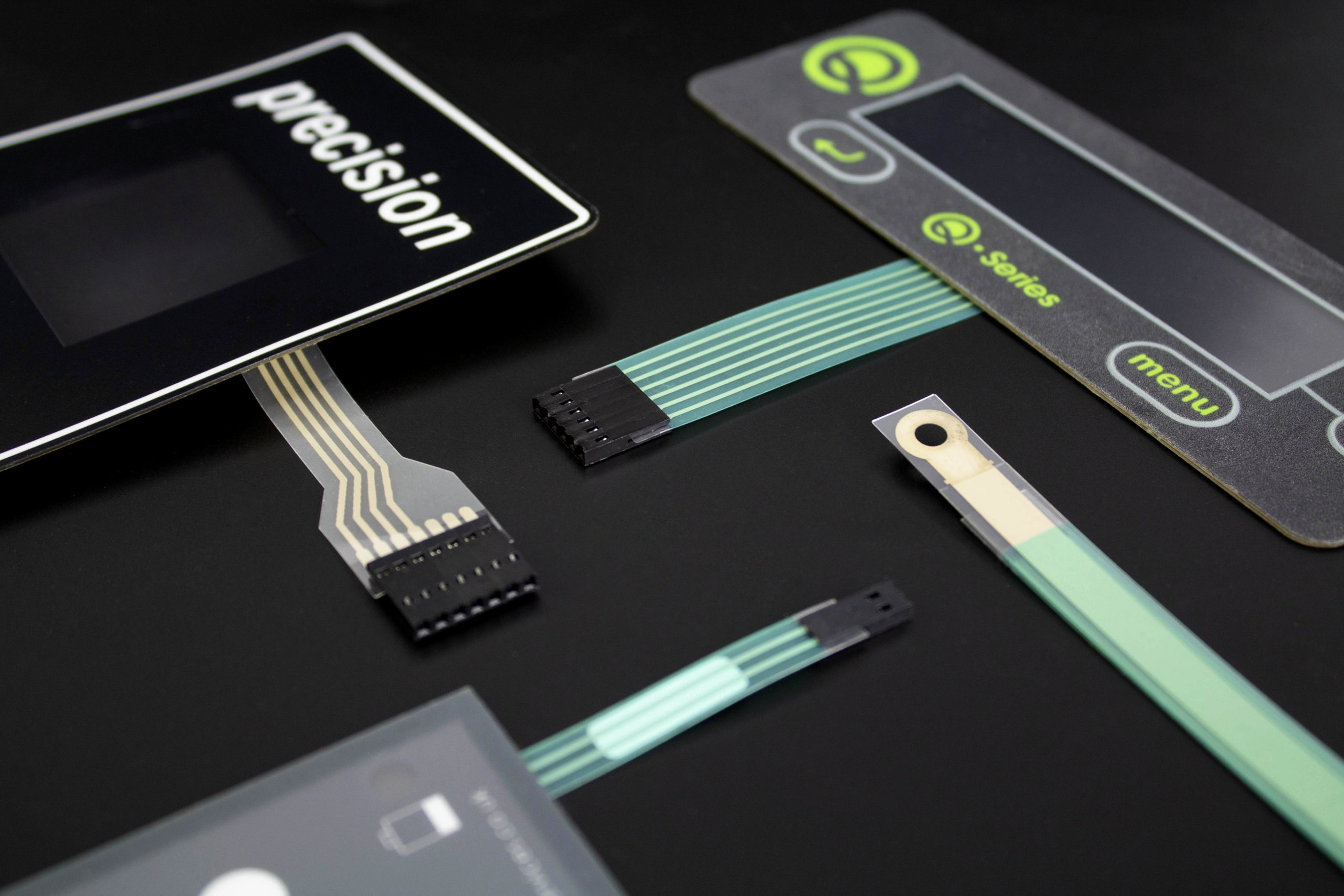

The products generally used in membrane layer button building and construction consist of polyester, polycarbonate, adhesive layers, published graphics, and conductive inks. These parts ensure responsiveness, longevity, and adaptability, making them appropriate for numerous electronic applications in diverse fields.

Just How Do Membrane Switches Over Compare to Standard Buttons in Resilience?

Membrane changes typically offer remarkable durability compared to typical switches, as they are much less vulnerable to mechanical deterioration. Their sealed layout safeguards versus dirt and wetness, boosting durability in different applications.

Can Membrane Layer Switches Be Personalized for Certain Applications?

Membrane buttons can undoubtedly be personalized for particular applications. Their layout versatility allows for customized forms, graphics, functionalities, and sizes, making them ideal for varied settings and boosting individual interaction across various electronic devices and equipment.

What Are the Ecological Factors To Consider for Membrane Switch Over Disposal?

The ecological factors to consider for membrane button disposal consist of potential dangers from materials used, recycling chances, and adherence to laws. membrane switch. Appropriate disposal methods are vital to minimize ecological effect and advertise sustainability within producing procedures

How Do Membrane Layer Switches Influence User Experience in Instruments?

Membrane layer changes significantly boost customer experience through tactile comments, toughness, and layout versatility. Their seamless assimilation right into tools promotes user-friendly interactions, while their aesthetic allure can boost product presentation, inevitably adding to user satisfaction and engagement. The tactile comments provided by membrane layer switches over improves user interaction, guaranteeing a smooth experience.Moreover, membrane layer switches are immune to dampness and dirt, which is crucial for preserving performance in everyday atmospheres. In addition, membrane layer buttons can be customized with different graphics and formats, guaranteeing that they satisfy certain requirements of different medical applications. Membrane buttons are additionally resistant to moisture and impurities, making certain longevity and long life in various cabin and cabin applications. Membrane switch technology is significantly finding applications in industrial automation, where reliability and efficiency are extremely important. Membrane layer switches usually supply superior sturdiness contrasted to conventional switches, as they are less vulnerable to mechanical wear and tear.